• Home • History • Design • AIA Award • Historic Registry • Press • Dedication

-

The concept seemed solid, but could the structure be equally so?

-

-

Young architect, Charles Lamb inquired with RTKL’s consulting structural engineer at the time. “Charlie, what have you brought me now?” was his initial response. “I have no books for this!” He then went on to advise Charlie that the eleven 32 ft. long support beams required for the Tepee would have to be at least 8 in. x 16 in. thick. Some confusion ensued. No beams this size were available at local lumberyards, and even if they were, the handling of them would be a challenge beyond the scope of the volunteer construction crew.

-

-

What appeared at first as an impasse, however, gave birth to an idea. Enter the Senior Math Professor, Reginald Lamb (Charlie’s father), of the Naval Academy.

-

”Analyze the structure as a single cone,” said Reginald, “not as many independent timbers joined together.”

-

-

Charlie had his answer. In an interview with the Baltimore Sun a year later he is quoted as saying, “In following his suggestion to let the entire form be the structure, we arrived at the solution that makes the lodge to us more than just an interesting shape. It became an integral whole, designed to act as a unit against any concentrated wind or snow loads.”

-

-

How was it done?

-

-

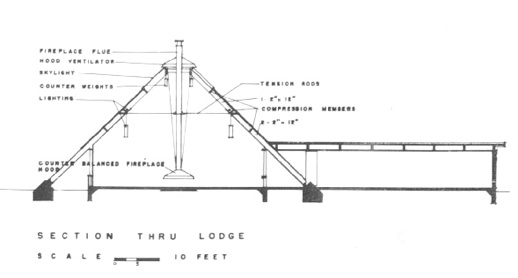

First, in order to avoid using the heavier support timbers suggested by the engineer, Charlie proposed using two 2” x 12” timbers bolted together with spacers for the lower portion of the structure, then anchoring these into the ground with concrete buttresses. (see photo)

-

-

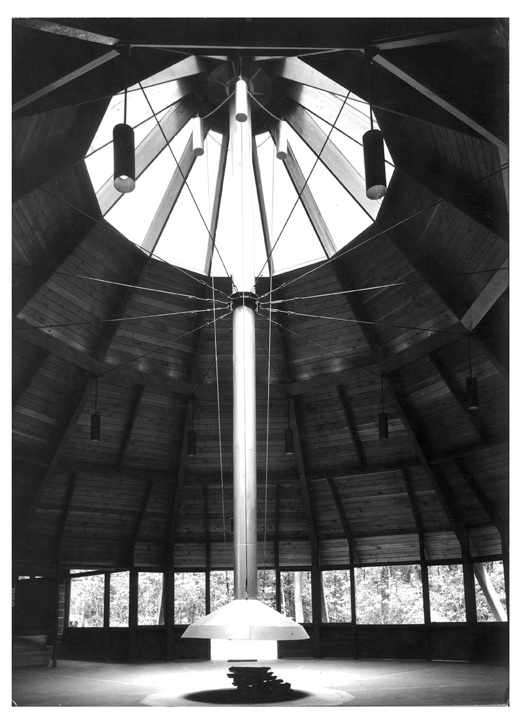

Halfway up, inside the tepee (at the point where the lower lights are strung), this tandem unit would then turn into a single 2” x 12” beam (the end of the single beam bolted in the space between the two lower beams) and extend up to the top of the structure where all of the timbers would then be joined by a steel ring. Next, instead of using standard smaller-width lumber for the 600 or so boards that made up the tepee’s roof, Charlie substituted 2” x 6” tongue and groove sheathing, that, once firmly fitted and mitered end to end, would act as horizontal compression rings encircling the structure. And finally, to reinforce these rings, again, inside, halfway up, steel cables would be attached to all the twelve main units so that they could be drawn together to a central steel ring with turnbuckles and thus be cinched tight. The tension would serve to make all parts into a single structural unit, i.e. a cone.

-

As a matter of note: with all of the exact measurements and precise mitering needed to insure success, Charlie had faith that Reginald’s team of volunteers from the Naval Math Department were up to the challenge. In the end, the quality of the construction can be attributed to their careful work.